The Final 1% That Cannot Be Filled by AI Alone

No matter how sophisticated the AI, the “1% risk hidden behind 99% detection accuracy” still remains.

You might think, ‘Isn’t 1% acceptable?’ But the situation is different in a manufacturing environment. That missed 1% error can translate into hundreds or thousands of actual defects, leading directly to customer claims and production shutdowns, resulting in massive cost losses.

A greater problem is the constantly changing environment. In an environment where new defect types continuously emerge, if unverified exception data is absorbed directly into the learning process, the detection rate may actually decrease over time.

Thus, it is difficult to perfectly control the ‘exception cases’ that occur on-site using AI automation alone. Maintaining model stability is also not easy. So, how can this problem be solved?

The answer lies not in simply adopting an AI model, but in establishing a ‘field-centric data curation structure’ that can improve performance based on real-time data generated on-site.

LaonPeople’s ADC System (Automatic Defect Classification System) is a solution equipped with this structure for automated learning and data improvement. It fills the ‘final 1% gap’ that AI fails to capture, achieving complete quality control.

What is the ADC System?

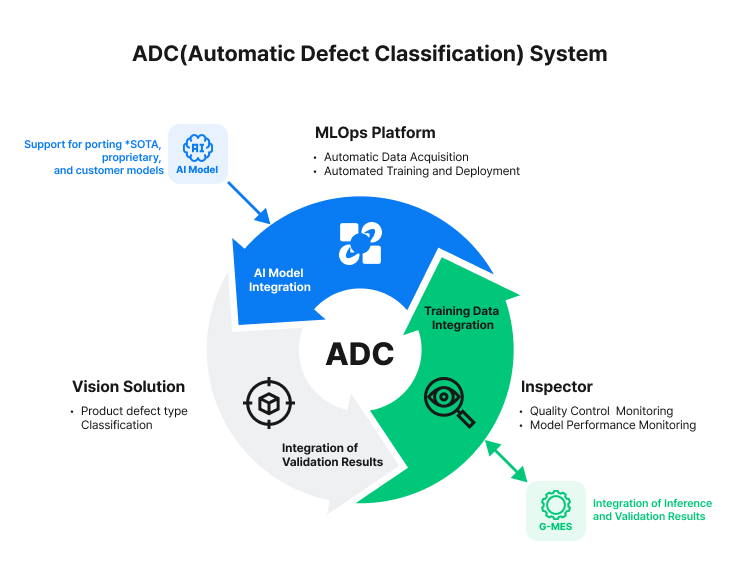

The ADC System is an automated defect classification system that integrates an AI model, a solution, an inspection system, and an MLOps platform into one. Simply put, it is a human-inspection combined control system designed to complement the limitations of existing AI Vision + MLOps automation and bring the defect rate on the production line ‘closer to zero.’ It essentially acknowledges the reality that AI is not omnipotent and seeks to maximize accuracy while minimizing human intervention.

While existing MLOps platforms can automate defect inspection, it has been difficult to avoid the degradation of inspection accuracy (model performance decline) over time. Introducing the ADC System ensures not only automation but also the maintenance of optimal inspection accuracy at all times. Let’s look at how this is possible.

The 3 Core Components of the ADC System

The ADC System consists of three core elements: the AI Platform, the AI Vision Solution, and the Inspector.

1. AI VISION SOLUTION – In Charge of Inference on Site

This is an image-based inspection device. It captures the product status with a camera installed next to the line and converts the data for AI analysis. Various AI models are ported to judge the product’s quality (pass/fail) and classify defect types. Simply put, its role is to handle inference on the production floor. It is equipped with optimized detection algorithms tailored to the characteristics of various industries.

2. MLOps Platform – Automation of Learning, Preprocessing, and Deployment

This is an automation platform that comprehensively supports AI model training, data collection, preprocessing, and deployment necessary for the vision solution to provide inference results and classify defects on-site.

Key Features:

- Centralized Data Preprocessing: Provides various preprocessing functions such as resizing, rotation, and cropping.

- Utilization of Existing Data: Existing labeled data can be used as is.

- GPU Resource Partitioning: The unique domestic feature of partitioning GPU resources in 1GB units for shared use.

- Auto Labeling Support: Provides various automated labeling features.

- Pipeline Automation: Automates the entire process from data collection to deployment and final verification, enabling large-scale operations with simultaneous model deployment across hundreds of production lines.

3. Inspector – The Core Differentiator

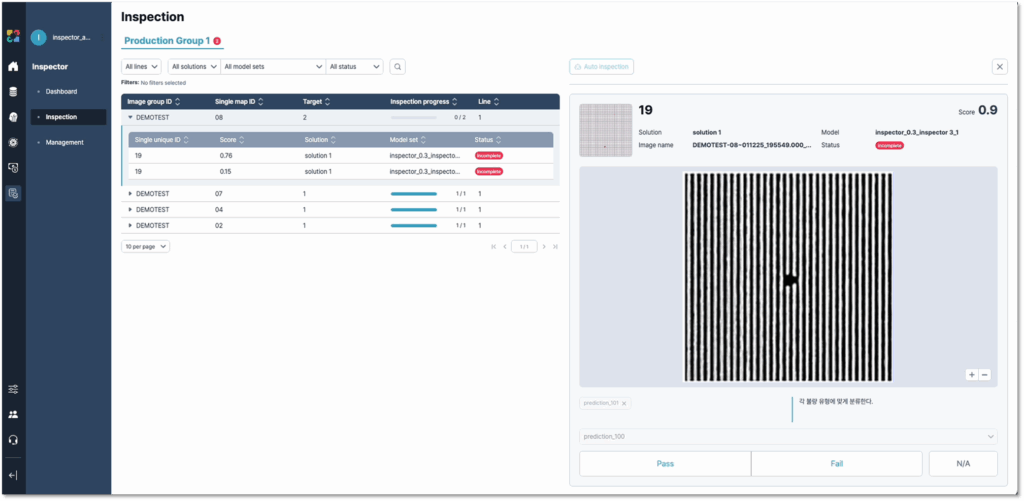

The key to the ADC System is the ‘Inspector,’ a structure that combines human verification. The Inspector system is designed so that a person only manually verifies the results produced by the AI model when the Confidence Score is below a certain threshold. In other words, only a small number of exception cases that the AI deems “uncertain” are forwarded to a human, while the vast majority are handled automatically by the AI. With minimal intervention, a human accurately compensates for what the AI might miss, and the AI, in turn, continuously improves model performance by learning from the exception data classified by human correction.

How Does the Inspector Work?

When the AI model performs inference, it also provides a Confidence Score, which indicates “how certain the judgment is.” The Inspector utilizes this point:

- High Score → AI handles automatically.

- Low Score → Forwarded to the Inspector.

- The human corrects the judgment (Correct/Incorrect) with a few clicks.

- The corrected data is automatically transferred to the MLOps platform.

- The platform initiates immediate retraining → Model is automatically updated → Automated deployment to the production line.

Thanks to this structure, operators only need to inspect 3-4 images out of 10,000 to stably maintain the overall model quality.

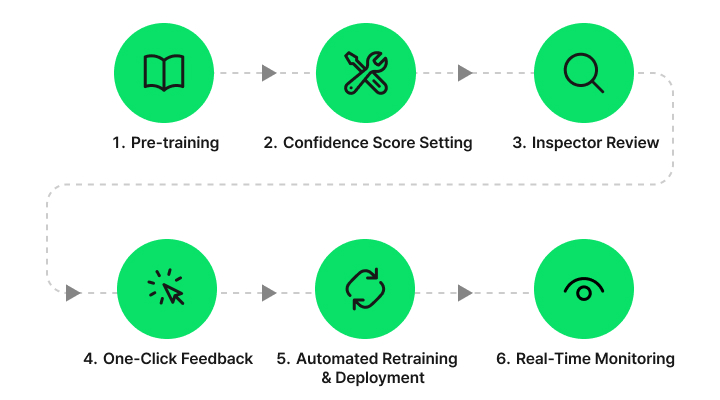

ADC System Operating Process

1. Pre-training: The operator completes initial model training according to defect types and prepares for deployment.

2. Confidence Score Criteria Setting: The reliability criterion for AI inference is flexibly set according to the product’s sensitivity.

- Sensitive products (Wafers, Secondary Batteries): High criteria set → More image inspection.

- Products allowing minor defects (Bolts, Materials): Low criteria set → Reduced inspection area.

3. Inspector Review: Humans review the low-confidence images selected by the AI to verify labeling errors.

4. One-Click Feedback: The review result is sent to the MLOps platform as labeled data with a single click.

- If AI judgment is correct: ‘Pass’

- If AI judgment is wrong: ‘Correct’ to provide the right label.

- New defect type: Handled as ‘NA (Not Applicable)’ for later training inclusion.

5. Automated Retraining and Deployment: The platform uses the feedback data to automatically conduct model training, testing, and deployment following the pipeline, thereby updating the model.

6. Real-time Monitoring: The entire process (inference, feedback, retraining) is checked in real-time via a dashboard, and inference data is linked with MES for actual production management.

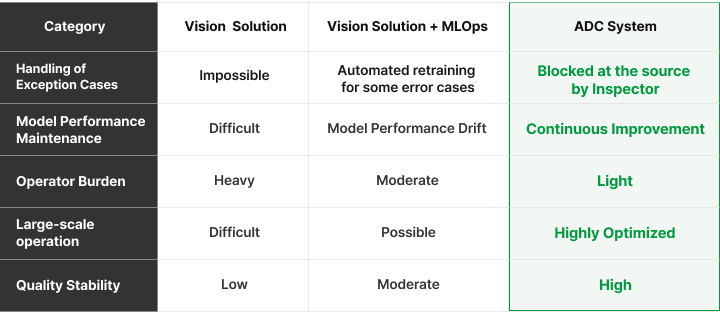

Performance Comparison Between Conventional Vision Inspection and ADC

📍 AI VISION SOLUTION

- All processes (data collection, labeling, AI training, testing, deployment, etc.) are conducted manually.

- Requires significant time and cost for optimized model operation and maintenance.

📍 AI VISION SOLUTION + MLOps

- Even with MES integration for automation, low-confidence defects are automatically absorbed, degrading AI model performance.

- Quality issues arise due to defects missed by the AI.

📍 ADC System

- Inspector performs intermediate verification >> Blocks erroneous data learning >> Maintains and improves AI performance.

- Prevents AI model performance degradation.

- Minimizes defect rate and manual inspection volume. Can be operated without specialized knowledge.

When is the ADC System Necessary?

- When achieving Zero Defects is a core requirement.

- When there is a lack of specialized AI personnel.

- For manufacturing industries such as steel, semiconductors, and secondary batteries.

- When integration with production systems like MES is required.

- When integrated management from field deployment to inspection is needed.

- When the goal is to automate quality inspection on the manufacturing floor.

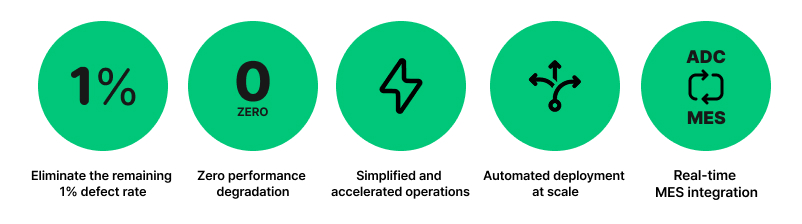

Changes Brought by Adopting ADC

📌 Captures the final 1-2% of defects.

Human correction covers the AI’s weak points, fundamentally preventing model contamination from incorrect data being automatically learned.

📌 Model performance is ‘consistently’ maintained

It prevents incorrect data from being automatically learned by the model and continuously learns new data generated on-site, ensuring the model’s performance does not degrade over time and always remains in optimal condition.

📌 Operators only need a few clicks

Operators can process all tasks with just a few clicks. Anyone can operate the system without complex AI knowledge, which is particularly advantageous for small and medium-sized manufacturers lacking specialized AI personnel.

📌 Large-scale deployment is also automated

Models can be automatically deployed to multiple production lines (10, 50, 100, etc.) at once and managed centrally.

📌 Seamless integration with MES

All necessary information for logistics and quality control, such as wafer ID, coordinates, and inspection equipment numbers, is immediately reflected in the process. Perfect integration with existing systems allows for immediate practical application without additional work.

Conclusion

The ADC System complements the AI blind spots on the manufacturing floor with human intervention, automating the cyclical structure where that human judgment makes the AI smarter, thereby realizing ‘complete quality control.’

Through this, companies simultaneously achieve four key effects:

- Human accurate judgment intervenes in uncertain cases, reducing the defect rate.

- Real-time quality monitoring and an immediate response system stabilize the process.

- The removal of erroneous data via the Inspector and continuous retraining maintain stable model performance.

- Automation of repetitive tasks allows for efficient resource allocation.

The ADC demonstrates the true meaning of ‘operating’ AI on-site and was recognized for its technological prowess by winning the Gold Prize in the Smart Factory AI Vision Sector at the ‘AI Science and Technology Innovation Awards 2025’ on November 5th.

The final 1% completeness that AI alone could never achieve, Stable performance that does not degrade over time, And accessibility that anyone can easily manage.

The challenge towards 100%, not 99%, is possible with the ADC System.