99% accuracy may seem sufficient, but in the manufacturing environment, that remaining 1% translates to hundreds or thousands of defects. The bigger challenge lies in the constantly changing production environment. As new defect types and exceptions arise, AI alone struggles to achieve perfect detection. This is why human verification is required.

ADC SYSTEM

Quality Inspection System that Captures Even the Last 1% Missed by AI

AI Stops at 99%.

True Quality Control Starts by Closing the Final 1% Gap

With the ADC System,

We Guarantee Perfection for the Last 1%.

- Overview

- Process

- Features

- Applications

- FAQ

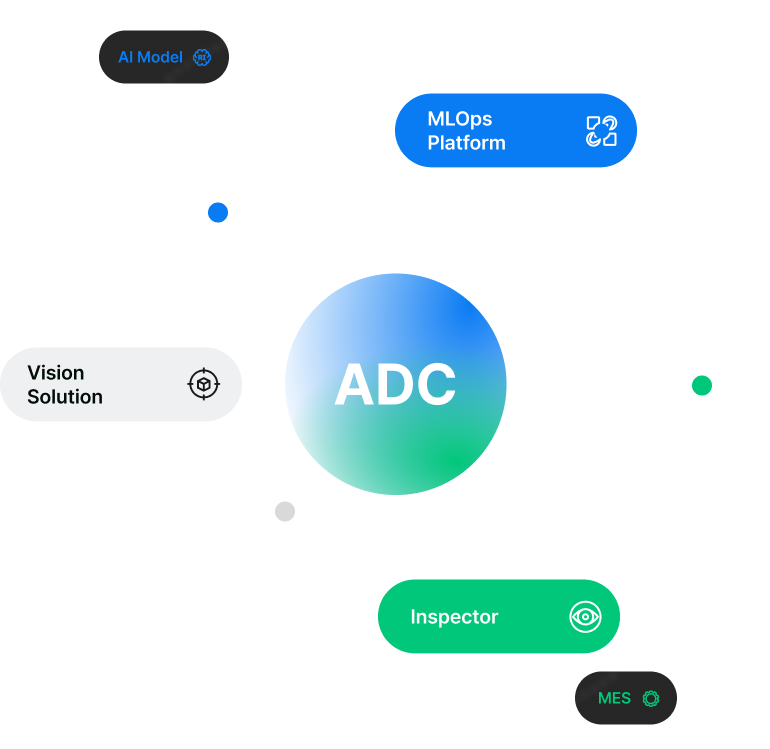

What is the ADC (Automatic Defect Classification) System?

ADC System is a quality management system that unifies the AI Model, Inspection System, and MLOps into a single integrated solution.

It maintains perfect quality through real-time data curation, even in factory environments facing a torrent of exceptions.

-

Vision Solution

A real-time inference system that photographs and analyzes products on the production line to immediately identify defects.

-

MLOps Platform

An integrated operational framework that automates the entire process, from data preprocessing and model training to deployment.

-

Inspector

A system where humans inspect only the exception cases that the AI is uncertain about, fundamentally blocking incorrect learning.

Through a 6-step automation structure,

the final 1% of errors is perfectly eliminated.

Process

-

01

Pre-training

- Pre-training on Defect Types

-

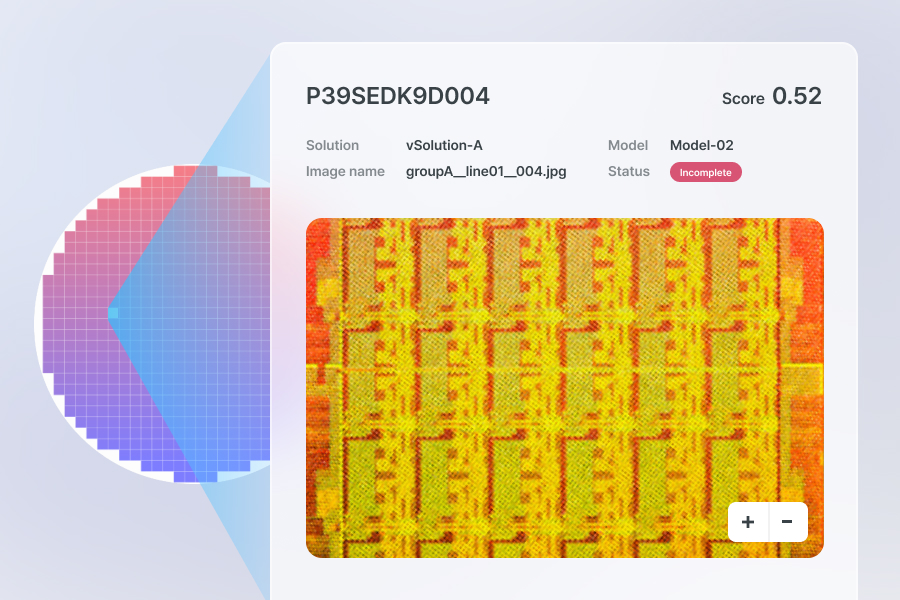

02

Confidence Score Setting

- Set according to the desired defect detection rate

-

03

Inspector Review

- Collecting low-confidence images filtered by the AI model human intervention for final inspection and label correction.

-

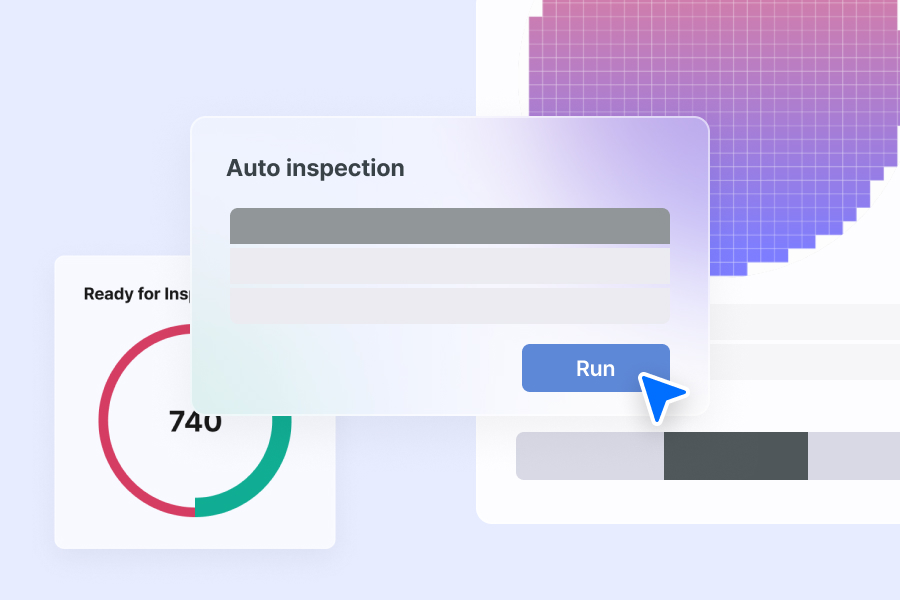

04

One-Click Feedback

- Transfer Label Data to MLOps

- Classification as Pass / Modify / NA

-

05

Automated Retraining & Deployment

- Automated Learning, Testing, and Deployment via the MLOps Pipeline

-

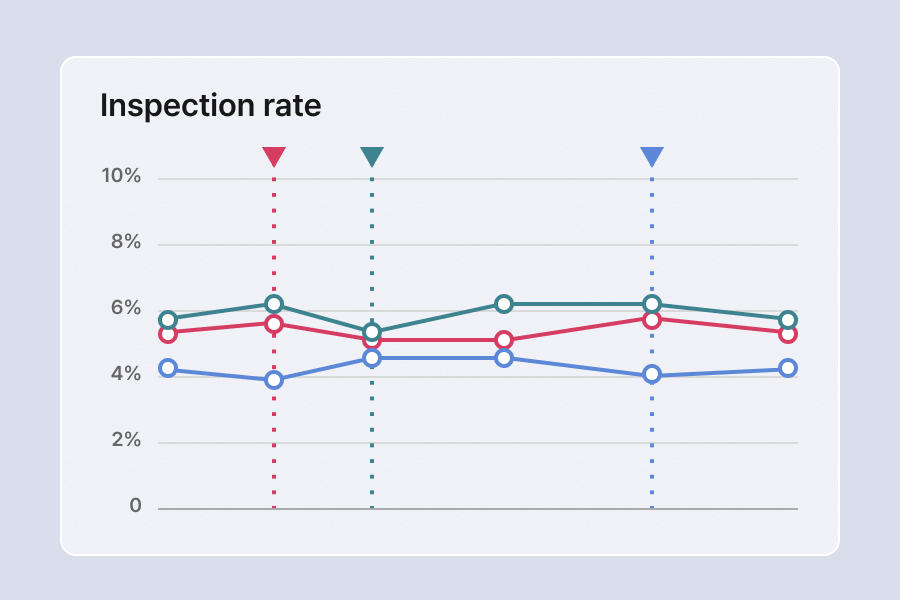

06

Real-Time Monitoring

- Real-Time Checking via Dashboard and MES Integration of Inference Data.

ADC eliminates both the limitations of manual operation

and the uncertainty of automation.

Features

-

01

Is the Final 1% Missed by AI Making You Uneasy?

The Inspector Eliminates

the 1% Defect RiskAI-uncertain data is validated by human operators via the Inspector module.

This fundamentally blocks erroneous automatic learning, ensuring the complete elimination of the remaining 1% defect rate.

-

02

Are You Letting Model Performance Drop Over Time?

Always Operating at Peak Performance

The system avoids incorrect data.

Instead, it continuously learns only field-verified new data, guaranteeing optimal performance without decay over time.

-

03

Are you still relying on specialists for hands-on AI operation?

Effortless Operation Without Specialized Expertise

Operators can instantly update the AI with field knowledge in just a few clicks.

No specialized AI expertise is required, ensuring immediate adoption without the need for additional hiring.

-

04

Wasting Time with Line-by-Line Model Deployment?

Automated Deployment for Large-Scale Lines, All at Once

The model is automatically deployed simultaneously to all production lines, whether you have 10 or 100.

All lines can then be centrally and uniformly managed.

-

05

Does it integrate with existing Production Management Systems?

MES Integration Available

All information required for logistics and quality management such as Wafer ID, coordinates, and inspection equipment numbers is immediately reflected in the process.

It seamlessly integrates with your existing MES system, allowing for immediate practical application without any additional work.

We provide tailored solutions for every industry.

Applications

-

Display

-

Electrical & Electronics

-

Materials

-

Semiconductor

-

Automotive

-

Steel

FAQ

Why do I need the ADC System when AI alone should be enough?

How Does the Inspector Work?

The AI calculates a "Confidence Score" for each decision it makes.

Human review is performed through the Inspector only when this score falls below a preset threshold.

In most cases, operators only need to manually review a very small fraction of the total images (e.g., about 3–4 out of 10,000), which significantly reduces the operational workload.

Which environments or industries are best suited for the ADC System?

The ADC System is especially valuable in the following situations:

- Manufacturing processes where zero defects—or extremely low defect rates—are critical, such as semiconductors, secondary batteries, or precision components.

- Companies lacking in-house AI experts but still needing high-performance visual inspection.

- Factories that need to automate vision inspection across multiple production lines at a large scale.

- Environments that require seamless MES integration, where inspection results must flow directly into production, logistics, and quality management processes.

Can we use our existing AI data or labeling information?

Yes, absolutely.

Your existing datasets, labeling assets, and inspection history can all be fully utilized within the ADC System.

Can the ADC System integrate with MES or existing factory systems?

Yes, it can.

ADC automatically synchronizes essential process data from your MES—such as wafer IDs, coordinate information, and inspection equipment numbers—in real time.

It is designed to connect seamlessly with your existing manufacturing IT systems, allowing immediate on-site use without conflicts or additional adjustments.