“Our company needs to implement Manufacturing AX—but where do we even begin?”

Driven by government initiatives supporting Manufacturing AX (AI Transformation), it’s not just tech giants anymore. Small and medium-sized enterprises (SMEs) are increasingly looking toward 2026 as a target year to enhance operational efficiency and quality control through AX.

Today, Manufacturing AX has shifted from a “nice-to-have” option to an inevitable mandate. However, the real challenge lies in the starting point. Between sensor data integration, MES connectivity, AI inspection models, Agents, and AAS, the sheer volume of technical jargon can be overwhelming. For departments tasked with AI adoption, distinguishing the preparation phase from the execution phase is no easy feat.

To address these concerns, Laon People provides an integrated Manufacturing AX architecture centered around our AI Agent platform, Hi FENN, empowering manufacturing sites to achieve a truly practical AI transformation.

The Laon People Manufacturing AX Portfolio

We offer a comprehensive suite of AX solutions designed to work seamlessly together:

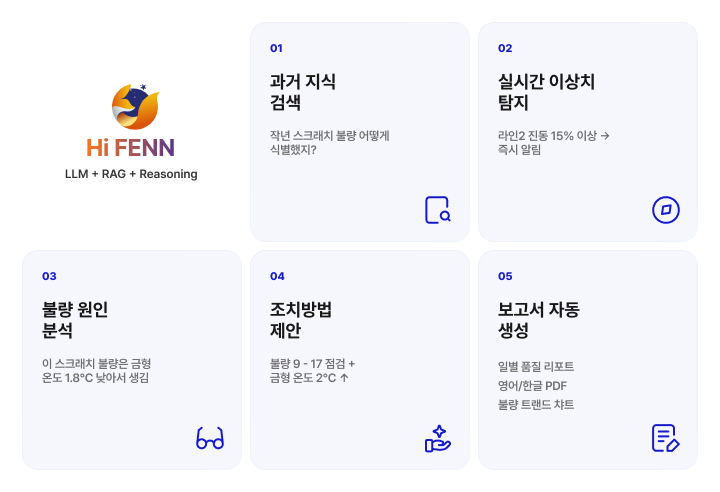

- Hi FENN (AI Agent Platform): A platform for building agents that utilize RAG (Retrieval-Augmented Generation) to search historical defect reports and support real-time data analysis and decision-making.

- EZ PLANET (MLOps Platform): Streamlines the development, deployment, and monitoring of machine learning models.

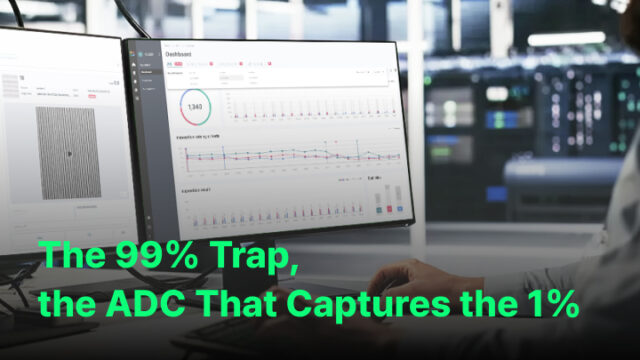

- ADC SYSTEM (Automatic Defect Classification): An integrated quality management system that combines AI models, inspection systems, and MLOps.

- NAVI AI PRO (AI Vision Inspection Software): High-performance software for AI-based vision inspection.

- AI Vision Solution: A turnkey service providing custom AI vision model development and optical design.

- ODIN AI: A security solution using Vision-Language Models (VLM) to analyze CCTV feeds for worker safety, data leak prevention, and intruder detection.

While each solution is powerful on its own, their true potential is unlocked when integrated through Hi FENN for unified data analysis.

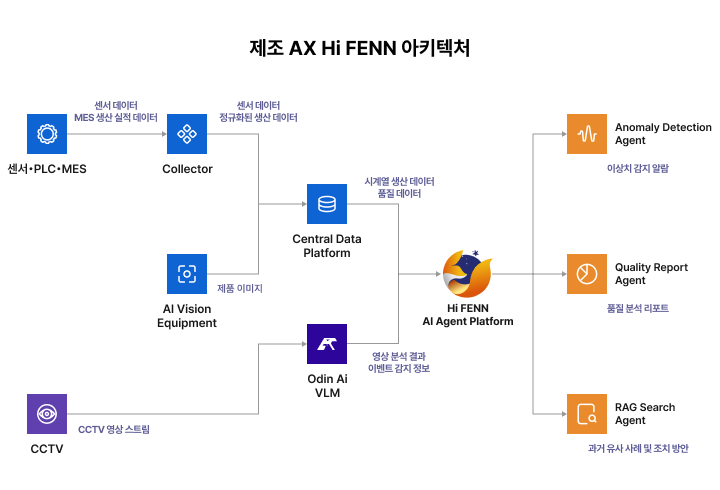

Manufacturing AX Architecture Powered by Hi FENN

Hi FENN is an enterprise AI Agent platform powered by LLM, RAG, and Agent technologies.

It turns your messy old documents—like past defect reports—into a smart knowledge base. By syncing up with your sensors, MES, and vision inspection data, the AI agent takes over the heavy lifting: it automatically detects anomalies, analyzes what caused a defect, and even cranks out your end-of-month reports for you.

What Manufacturing AX with Laon People Looks Like

What exactly happens when you bring Laon People’s Manufacturing AX portfolio into your factory? Let’s look at a few real-world examples:

1. Real-time Anomaly Detection: Stop Breakdowns Before They Happen

Using our dedicated Collector, we gather sensor data in real-time and send it to a central data platform. Here’s where the Hi FENN Anomaly Detection Agent kicks in. It constantly monitors for weird patterns in temperature or vibration.

- The Workflow: Sensor Data → Data Collector → Data Platform → Hi FENN Agent

- The Result: “Alert: Unusual temp pattern detected in Line 2. Similar to 3 past cases. Suggest checking Valve B-17.” (Auto-alert sent!) By catching these glitches early, you can prevent costly equipment failures and keep your downtime to an absolute minimum.

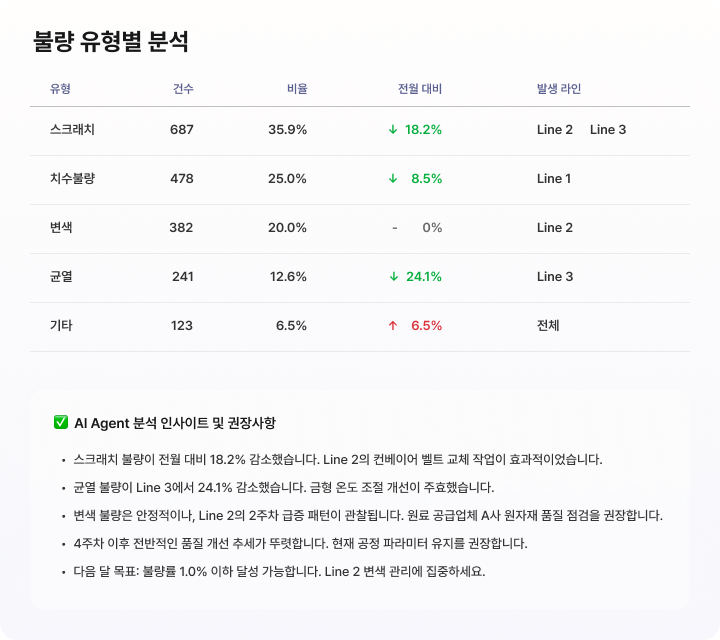

2. Quality Report Agent: Finish a Month’s Worth of Reports in 5 Minutes

Writing reports is a chore, but not anymore. A Hi FENN Agent synced with your MES handles the heavy lifting:

- Analyzing monthly defect trends

- Visualizing defect frequency by type

- Identifying what got better (or worse) compared to last month

- Auto-generating the full quality report

All the quality manager has to do is a quick 5-minute review!

3. End-to-End: From Inspection to Root Cause Analysis

Our AI vision equipment sends product images straight to the data platform. Algorithms developed with NAVI AI PRO analyze the images, while our Quality Inspection Agent automatically calculates metrics like defect rates. If a defect is found, the agent uses RAG (Retrieval-Augmented Generation) to find similar cases from the past.

- The Magic: It might suggest, “November 2023: Same defect occurred with Client A. Solved by lowering mold temp by 2°C.”

- Now, even a rookie technician can work with the 10-year know-how of a veteran.

4. ODIN AI: Security & Safety on Autopilot

ODIN AI is our generative AI surveillance solution. Using VLM (Vision Language Model), it watches your CCTV feeds to prevent accidents and detect unauthorized access or information leaks in real-time. Compared to old deep-learning systems, it has far fewer false alarms and keeps your site secure 24/7. a wider variety of events, such as safety violations or unauthorized data access, ensuring 24/7 security.

The Value of Transformation

The government has recently doubled the budget for AX expansion, specifically increasing support for “AI Factories.” In these initiatives, “Agentic AI” is a key requirement. The Hi FENN team helps clients leverage these subsidies to transition to AI with minimal financial burden.

Why choose a Hi FENN-centric AI transformation?

1. Preserving Manufacturing Expertise

The skilled labor shortage in manufacturing is getting worse every year. Junior technicians are having to step in for retiring veterans, but for smaller companies, vital “know-how” often isn’t documented—it’s just stuck in people’s heads as implicit knowledge.

By setting up Hi FENN, you can turn every past defect record and its solution into a structured Knowledge DB. This allows junior techs to easily tap into years of veteran expertise through RAG-based search. Plus, once it’s running, new insights are constantly added to the system, leveling up the entire organization’s problem-solving skills!

2. Cutting Defect Rates and Slashing Manufacturing Costs

- 20-30% Reduction in Defect Rates: Stop quality issues in their tracks with AI-powered real-time monitoring and predictive maintenance.

- 50% Faster Reporting: Cut the time spent on tedious end-of-month quality reports in half.

- 30% Less Downtime: Minimize unplanned equipment stops by catching warning signs early.

- Lower Operating Expenses : Save big by optimizing labor costs and reducing the price of re-working defective parts.

3. Stress-Free FMEA Creation and Management

Setting up Hi FENN makes the FMEA (Failure Mode and Effects Analysis) process—a must-have for global quality certifications like ISO 9001—over 30% easier.

- Instant Access to History: Use the RAG search to instantly pull up past defect data and fix histories. This drastically cuts down the time needed to identify potential failure modes and analyze their causes.

- Easy Data Gathering: Since sensor data and quality histories are systematically managed, you can easily grab the exact data you need for both DFMEA (Design) and PFMEA (Process) documentation.

- Ready for Audits: When it’s time for a quality certification audit or a client inspection, you can quickly search for past cases and improvement records to use as solid evidence for your FMEA reports!

Get Ready for 2026 Manufacturing AX Today!

Laon People is here to be your long-term partner for the AX journey. Our clients haven’t been waiting around—since last year, they’ve already been building RAG-based knowledge DBs, deploying AI Agents for automation, and syncing those agents with their core system data.

If you’re looking into 2026 Manufacturing AX, now is the perfect time to reach out. Consultations are handled on a first-come, first-served basis, and since our slots are limited, we highly recommend signing up early.

Let’s make 2026 the year you realize your Manufacturing AX goals with Laon People!