Most manufacturing processes (assembly, machining, printing, packaging, etc.) can be adapted for vision inspection.

Provide us with a sample product or drawing, and we will conduct a preliminary review.

AI VISION SOLUTION

Integrated Custom Vision Inspection Service,

Revolutionizing Manufacturing Productivity from Design to Implementation

We provide customized solutions

that deliver AI-enhanced flawless quality control

and dramatically reduce manufacturing defects.

Laon People's AI Vision Solution,

Proven in Countless Industrial Sites

AI now addresses the fatigue and subjectivity of repetitive visual inspections.

Achieve quality improvements and cost reductions with Laon People's high-quality solution, backed by 15 years of expertise and over 400 successful projects.

-

15

Years

-

400+

Project

- Technical Capabilities

- Process

- Features

- Applications

- FAQ

We have extensive technical expertise

spanning the entire AI vision inspection workflow.

Technical Capabilities

-

AI Visual Inspection

- Battery

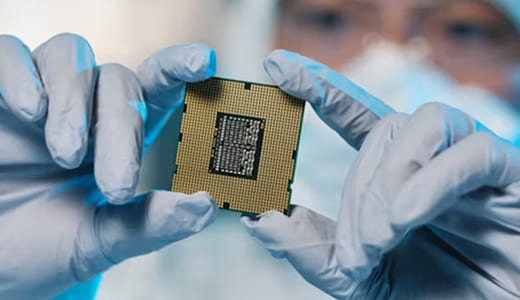

- PCB

- Wafer

-

AI Platform

- MLOps

-

Automated Inspection Equipment Design & Manufacturing

- AFVI

-

2D/3D Camera Imaging

- 2D Machine Vision Cameras

- 3D Cameras

- Edge Device

- Smart Cameras

-

AI Algorithms

- Classification

- Detection

- Segmentation

- Unsupervised Learning

- Active Learning

-

Optics & System Design

- Micrometer-level Precision Optics

- Lighting Specialized for Multi-camera Systems

- Ultra-high Resolution High-speed Camera

- Modular Opto-Mechanical Integration

Systematic Processes and Expertise:

Providing Fast and Accurate Solutions

Process

Consulting

-

01

Customer Requests

& ConsultationConsultation on Customer's Inspection Targets and Environment

-

1 Week

Conducting

Meetings -

02

Requirement Review

Requirement Review and Proposal Preparation

-

2 Weeks

Delivery of Review

and Proposal Document -

03

Proposal Delivery &

Secondary ConsultationFollow-up Consultation with Customer Based on Proposal

Development &

Implementation

-

Keep Existing Equipment, Software-only Implementation

1 Month -

Add Only Optical Structure and Software to Existing Lines

2 to 3 Months -

Implement Software, Structure, and Inspection Equipment

3 Months or More

Combining Industry Expertise with AI Technology

to Deliver Optimal Custom Solutions

Features

-

01

End-to-End Services Built

on ExpertiseFrom process flow analysis to environment design, AI algorithm development, and HW-SW integration – all in a single streamlined process.

-

02

Providing Customized

Solutions Based on

Extensive Industry and

Domain Expertise- Providing customized solutions across a wide range of industries, including semiconductors, displays, secondary batteries, automotive parts, food & beverage, and pharmaceuticals.

- Exceptional competitive advantage, especially in precision parts with fine and complex defects

-

03

Customer-tailored AI

Customization- Customize AI models optimized for your inspection target, environment, required accuracy, and more

- Flexible from high-volume, single-variety to low-volume, multi-variety production environments

-

04

Seamless Integration with

Existing SystemsAccurate detection reduces false positives and increases efficiency.- Easily integrate with existing manufacturing IT systems such as MES, ERP, and more

- Enable rapid adoption and sustainable operations

We provide tailored solutions for every industry.

Applications

-

Display

-

Electrical & Electronics

-

Materials

-

Semiconductor

-

Automotive

-

Steel

FAQ

Which products are eligible for vision inspection?

How does the advance review work?

We receive the defective sample, conduct a preliminary review (free or paid), and provide recommendations based on the results.

What types of defects can be detected?

AI can detect and classify multiple defect types, including scratches, dents, foreign objects, contamination, color anomalies, and more.

How is pricing calculated?

Quotes vary depending on the system components (hardware and software).

Does it work with systems such as PLC/MES?

It is compatible with most PLCs, control systems, databases, and more.

Can I configure my system with just the CPU and no GPU?

Training: A GPU is required for model training.

Inference: Field-processing machines can be configured with CPU-only operation for high-speed inference under 1 ms.